MODERNIZATION OF ELECTRICAL SYSTEMS FOR HEAVY MACHINERY

ALTEN’s client is one of the world’s leading manufacturers of heavy machinery. From time to time, their machines need to be modernised so that they comply with today’s requirements. In this project, the customer solicited ALTEN’s engineering services for the modernisation of the electrical systems of their machines.

Lowering the carbon footprint through modernisation

The aim of the project was to update the old industrial machinery to meet today’s demands. This restoration included improving the usability of the machines, updating electronic components, and improving the durability and safety of the equipment.

The goal was to ensure the longevity of the machine’s service life. As a machine’s lifespan increases, the end user doesn’t have to invest in new machines so frequently, all while maintaining a low carbon footprint.

The project stakeholders from ALTEN’s side were composed of several electrical engineers and the project manager. On the client’s side, the project stakeholders included the engineering manager, his team, and the end customer.

ALTEN’s comprehensive role in electrical engineering

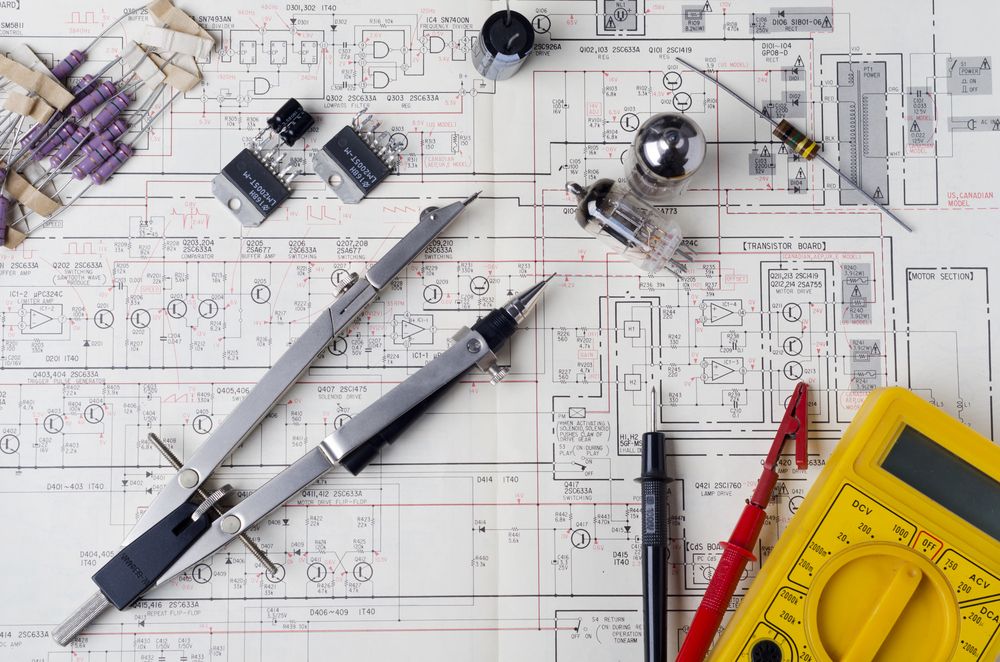

In this project, ALTEN’s role was to provide electrical engineering expertise in all areas identified by the client. For example, regarding electrical distribution planning, wiring harness design and 3D modelling of electrical systems.

ALTEN’s electrical engineers were responsible for the electrical design of heavy-duty machines by utilizing modern tools. The following design tools were used in the project: Siemes NX and Zuken E3. (A typical week in the life of the designers consists of electrical design tasks, collaboration with component suppliers, and participation in design meetings.)

The main challenge encountered throughout the project was adapting to the end consumer’s demanding operating environment, when performing the electrical design work for the machines.