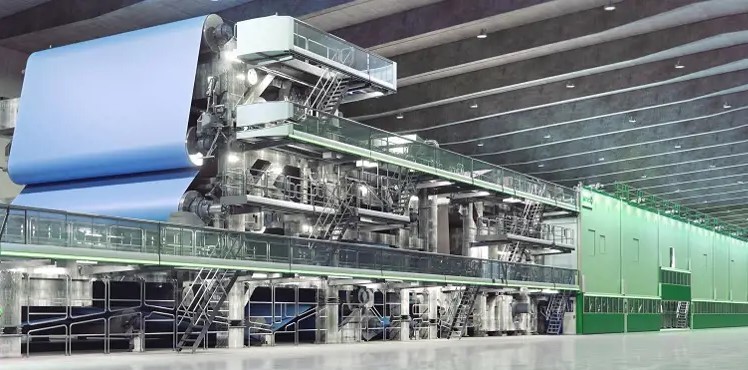

CONVERTING A PAPER MACHINE INTO A CARDBOARD MACHINE

ALTEN’s client is a global company that focuses on paper machine manufacturing. In this project, the aim was to convert a fine paper-making machine into a cardboard-making machine. The client’s need was due to the market shifting more towards digitalisation: the reliance on paper has decreased globally, as magazines and books, for example, have evolved from paper versions to the digital world, while the explosive growth of online shopping has increased the need for cardboard packages in the market. As a result, the customer commissioned ALTEN to design the mechanical detail design of the coating machine, enabling the fine paper-making machine to be converted into a cardboard-making machine.

The project progressed in stages

In the beginning of the project, the new technical parts needed for the machine were defined, after which the design work was carried out in collaboration with the customer. Following the design work, the customer was able to order the necessary technical parts, most of which were ordered readymade. The next stage was to deliver the new parts to the factory, where they were installed in the machine and tested. Finally, quality assurance was carried out before the machine was put into use again. The updated machine successfully produced cardboard instead of fine paper thanks to the technical parts designed by ALTEN.

The changes in the production machine were extensive and the entire project lasted about a year.

In addition to engineering, ALTEN was responsible for documentation

Over the course of this long-term customer relationship, ALTEN has developed considerable expertise in paper machine engineering. In this project, in addition to machine engineering, ALTEN was also responsible for the documentation (i.e. gathering and sending out the technical drawings). The documentation included the installation, use and maintenance of instructions, which ALTEN also distributed to the end consumer.

The designing software that was utilised in the project was Catia V6.

Project’s broad stakeholder group

ALTEN’s project stakeholders consisted of the project manager and the engineering team, including mechanical, electrical and fluid engineers, as well as technical documenters. The ALTEN team on the project was made up of about 30 experts from Finland and abroad. On the customer’s end, the stakeholder group included a project manager, chief designer and the engineering team.

(The challenges that were faced throughout the project were ensuring the schedule was respected and managing and readapting to changes. The challenges were overcome thanks to solid experience and cooperation.)